2006

Founded MAKEN Tech

Independently designed and manufactured Cash Drawer and POS accessory.

2010

Factory Relocation

A new factory had 11,000 square meters production area, with mold workshop and stamping workshop.

2011

Established R&D and Engineering Department

With customized service capabilities.

2013

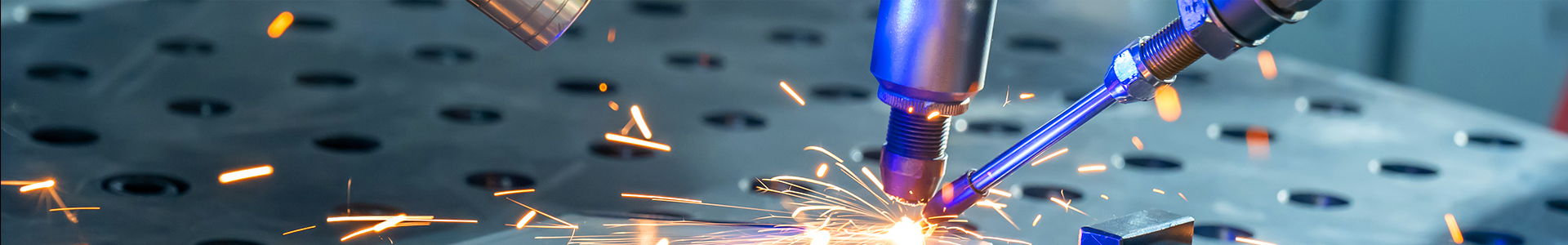

Large-scale Expansion of Production Capacity

Increased automatic assembly line, AMADA CNC punching machine, CNC bending machine, HASS CNC center, SODICK wire-cut machine, etc.

2016

Entered Intelligent Terminal Market

Independently develop new products of digital signage and kiosks.

2020

Building MAKEN Industrial Park

A one-stop manufacturing center.

2022

Industrial Park 1st Phase

1st phase of 4 workshops start running.

ABOUT MAKEN

CORE VALUE

R&D/ENGINEERING

MANUFACTURING

QUALITY STANDARD

HOME > About Us > ABOUT MAKEN